Zipper Sliders: A Comprehensive Guide

Zipper Sliders: A Comprehensive Guide

1. Introduction

A zipper slider (commonly called a "拉链头" in Chinese) is the movable component of a zipper that interlocks or separates the teeth/coils when pulled. It is a critical part of zipper functionality, enabling opening, closing, and locking mechanisms. Sliders vary in design, material, and application, tailored to garments, bags, footwear, and industrial uses.

2. Components of a Zipper Slider

-

Pull Tab: The handle used to move the slider.

-

Body (Bridge): The main frame housing internal mechanisms.

-

Top & Bottom Stops: Prevents the slider from detaching.

-

Locking Mechanism: Some sliders feature auto-lock or semi-lock systems.

-

Diamond/Logo Plate: Decorative or branding area.

3. Types of Zipper Sliders

-

Non-Locking Sliders: Basic design for lightweight items (e.g., dresses).

-

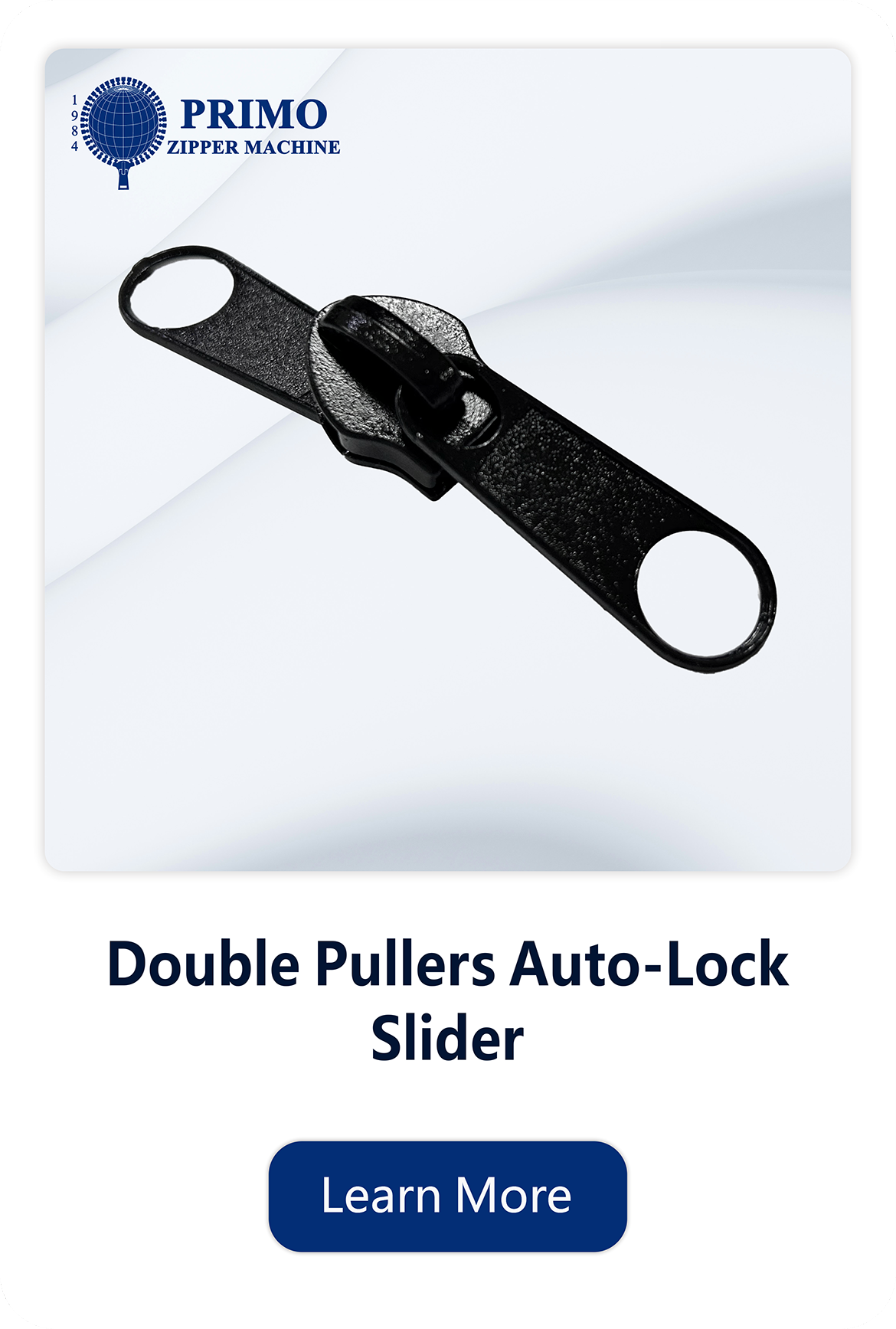

Auto-Lock Sliders: Locks automatically when pull tab is released (common in jeans).

-

Semi-Lock Sliders: Requires manual alignment to lock (used in jackets).

-

Two-Way Sliders: Dual sliders for bidirectional opening (e.g., backpacks).

-

Invisible Sliders: Hidden designs for seamless aesthetics (formal wear).

-

Heavy-Duty Sliders: Reinforced for luggage or outdoor gear.

4. Materials

-

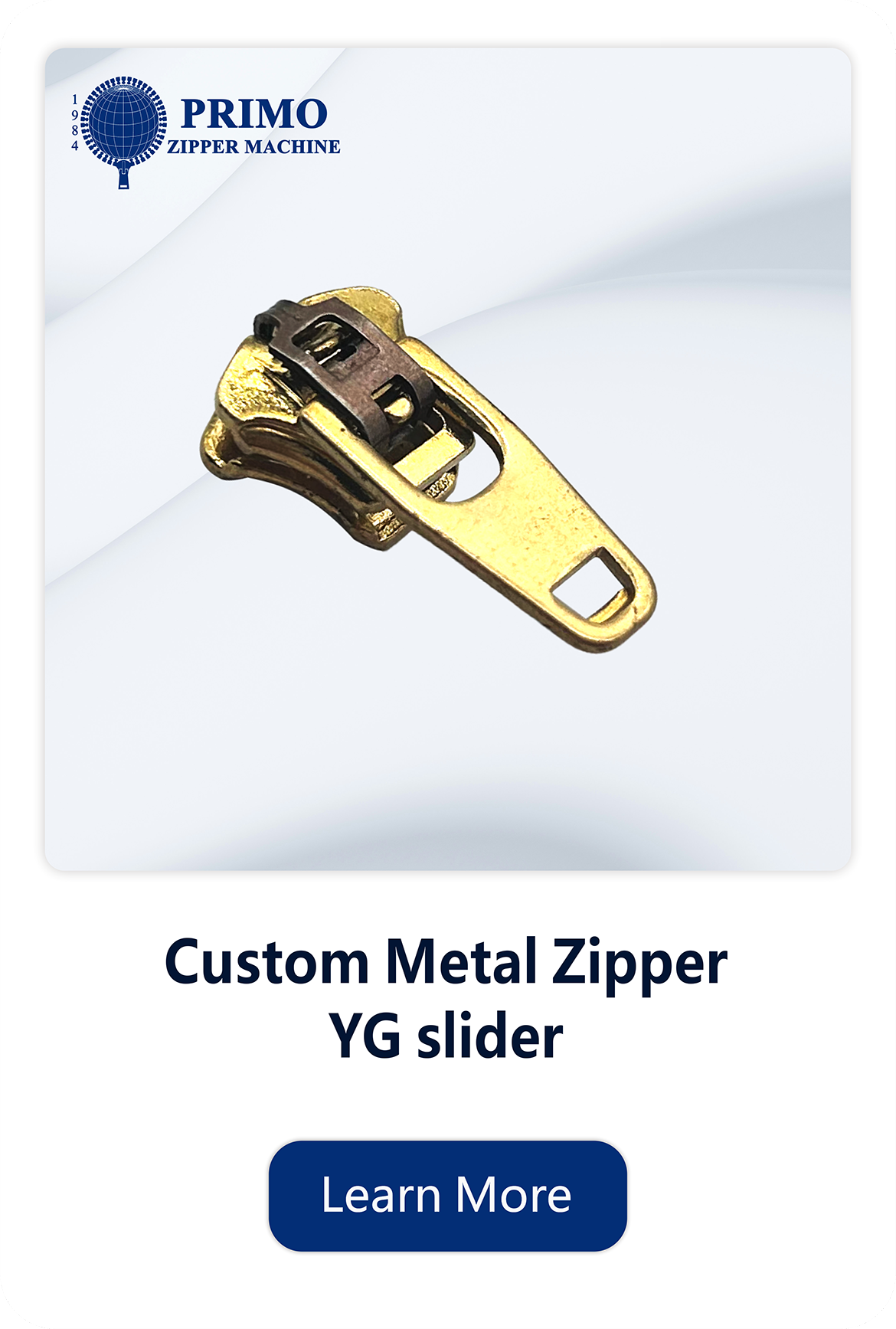

Metal: Brass, aluminum, or zinc alloy for durability (jeans, leather goods).

-

Plastic: Nylon or POM (polyoxymethylene) for lightweight flexibility (activewear).

-

Composite: Metal-plastic hybrids for balance.

5. Manufacturing Process

-

Die-Casting/Molding: Metal sliders are cast; plastic ones are injection-molded.

-

Assembly: Pull tabs attached, springs inserted for locking mechanisms.

-

Plating/Coating: Metal sliders may be nickel-plated or painted.

-

Quality Control: Stress-tested for smooth operation.

6. Applications

-

Fashion: Decorative sliders with logos or colors.

-

Outdoor Gear: Rust-resistant sliders for tents, wetsuits.

-

Medical: Sterilizable sliders for surgical gowns.

-

Automotive: High-tension sliders for seat covers.

7. Selection Criteria

-

Zipper Chain Compatibility: Must match tooth/coil size (e.g., #3, #5 sizes).

-

Environment: Corrosion-resistant for marine use.

-

Aesthetics: Custom shapes/colors for branding.

8. Maintenance & Issues

-

Stuck Sliders: Apply graphite or wax lubricant.

-

Misalignment: Realign teeth gently with pliers.

-

Replacement: Use pliers to remove old slider; insert new one.

9. Innovations

-

Magnetic Sliders: Self-aligning for effortless closing.

-

Eco-Friendly: Recycled materials.

-

Smart Sliders: Embedded RFID for luggage tracking.

10. Conclusion

Zipper sliders, though small, are precision-engineered for reliability. Understanding their types and functions ensures optimal selection for any application, from haute couture to heavy industry.